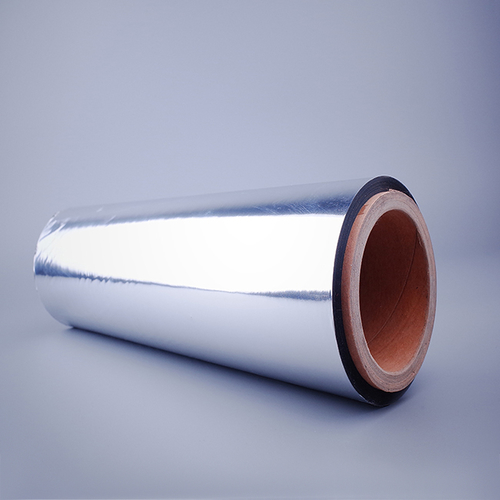

Candy Twist Film

Material:Plastic Film

In the modern packaging and printing industry, laminating film has become an indispensable material. Whether it is daily commodity packaging, book covers, or protective packaging of food and medicine, laminate films play a vital role in it. It can not only effectively extend the service life of the product, but also improve the appearance of the product and bring a better consumer experience.

Coated film is a surface treatment material, usually made of plastic film (such as polyester film, polyethylene film, etc.), which is firmly bonded to paper or other substrates through coating, hot pressing and other processes. There are many types of coating films, the common ones include glossy mask, matte film, anti-UV film, wear-resistant film, etc. Different types of laminate films have different functions and can be selected according to specific needs.

One of the most distinctive features of laminated films is their excellent protective capabilities. It can effectively block moisture, dust, oil and other environmental factors from damaging the substrate. For example, in food packaging, laminated films can prevent moisture loss and maintain the freshness of food; on book covers, laminated films can prevent books from wearing out due to repeated reading, extending the service life of books.

Laminated films can also significantly improve the visual effect of the product. Glossy masks can bring a bright sheen to the surface of the product, while matte films can give the product an elegant, low-key texture. In addition, laminated films can also form clear color contrasts on printed matter, making printed content more vivid and attractive. For some high-end products, the use of laminating films can also enhance the quality of the product.

Laminated films can increase the durability of substrates, especially when used outdoors or in high-intensity use environments. It increases the tear, abrasion and UV resistance of paper, card or packaging. For example, outdoor advertising posters are often laminated to cope with the challenges of prolonged exposure to sunlight and rain.

With the improvement of environmental awareness, more and more laminate films are made of degradable materials, which meet environmental protection requirements. In recent years, biodegradable membranes have gradually become a popular choice in the market. This type of membrane can not only complete the functions of traditional coatings, but also degrade quickly after use, reducing the burden on the environment.

Coated films are widely used in packaging, printing, advertising, electronics, medical and other industries. The following are some typical application scenarios:

Provide additional protection for food, prevent water evaporation or external contamination, and extend the shelf life of food.

Protects book covers from damage, moisture and stains while enhancing the visual quality of books.

It is often used to make posters, brochures and other materials to improve printing effects and enhance waterproof and UV resistance.

Use laminate film to protect business cards, certificates and other printed matter to make them more durable and long-lasting.