Candy Twist Film

Material:Plastic Film

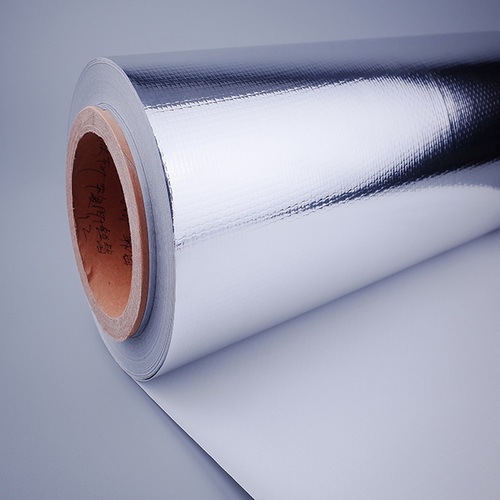

Aluminum foil coated fabric is an innovative material that has gained widespread popularity due to its unique combination of lightweight, durability, and high-performance properties. This fabric is created by bonding a thin layer of aluminum foil onto a fabric substrate, often made of polyester, fiberglass, or other synthetic materials. The result is a fabric that offers excellent heat resistance, reflective properties, and enhanced durability.

One of the standout features of aluminum foil-coated fabric is its superior heat resistance. The reflective aluminum layer helps to deflect radiant heat, making the fabric ideal for use in high-temperature environments. This makes it useful in industries where heat exposure is a concern, such as in automotive, construction, and manufacturing.

The aluminum foil coating gives the fabric excellent reflective properties. This ability to reflect heat and light is especially beneficial in applications where controlling temperature is critical. By reflecting sunlight, aluminum foil-coated fabrics can help to keep interiors cooler and reduce the need for air conditioning, making it an energy-efficient solution.

Aluminum foil-coated fabrics are typically resistant to tearing, abrasion, and weathering, providing long-lasting durability in harsh environments. The fabric’s strength makes it ideal for use in demanding applications where conventional fabrics may wear out quickly.

In addition to heat resistance, aluminum foil-coated fabrics are often highly water-resistant. The aluminum layer acts as a barrier to moisture, preventing water from penetrating the fabric. This feature makes it suitable for outdoor applications or in environments where moisture and humidity are prevalent.

Despite its durability, aluminum foil-coated fabric remains relatively lightweight and flexible. This makes it easy to work with and mold into various shapes, making it suitable for a range of applications, from industrial insulation to protective covers.

One of the primary applications of aluminum foil-coated fabric is in thermal insulation. The material is used extensively in the construction and automotive industries to insulate buildings, machinery, and vehicles from excessive heat. In buildings, the fabric can be used as an insulation blanket for walls, roofs, and attics, helping to regulate indoor temperatures. In vehicles, it is often used as a thermal barrier to protect against engine heat and improve energy efficiency.

Due to its ability to reflect UV rays and resist heat and moisture, aluminum foil-coated fabric is commonly used to make protective covers and tarpaulins. These covers are used in various industries, such as agriculture, construction, and storage, to protect equipment, vehicles, and machinery from the elements. For example, aluminum-coated tarps are used to cover agricultural products, ensuring they remain cool and protected from the sun.

Aluminum foil-coated fabric is frequently used as an outer layer for cables and wires in high-temperature environments. The reflective and protective properties of the aluminum foil help shield the cables from heat damage and interference, ensuring the cables perform reliably even under extreme conditions.

Aluminum foil-coated fabrics are used in the production of safety gear such as heat-resistant suits, gloves, and aprons. These items are particularly beneficial for workers in industries such as metallurgy, firefighting, and welding, where protection from high heat is essential. The fabric helps to prevent burns and injuries caused by exposure to extreme temperatures.

Aluminum foil-coated fabric is used in solar reflectors and energy-efficient materials. The high reflectivity of the aluminum layer helps to direct sunlight towards solar panels or other energy-absorbing surfaces, improving their efficiency. The fabric is also used in greenhouses to reflect sunlight onto plants, optimizing growth conditions and reducing the need for artificial lighting.

The reflective properties of aluminum foil-coated fabric can help to reduce energy consumption by reflecting heat and light. In construction, using this material for insulation or as a protective covering can help maintain desired temperatures without the need for excessive heating or cooling. In turn, this leads to reduced energy bills and a smaller carbon footprint.

Aluminum foil-coated fabrics provide a cost-effective way to enhance the performance of various products. They offer a high level of protection against heat, moisture, and UV rays, improving the lifespan of equipment and structures while reducing the need for frequent replacements or maintenance.

The use of aluminum foil-coated fabrics in insulation and protective coverings contributes to energy savings, which in turn reduces the environmental impact. Moreover, many aluminum foil-coated fabrics are recyclable, contributing to sustainability efforts in various industries.

Aluminum foil-coated fabrics can be easily customized to meet specific needs. They can be produced in different thicknesses, widths, and finishes, depending on the application. This versatility makes them suitable for a wide range of industries and use cases.