Candy Twist Film

Material:Plastic Film

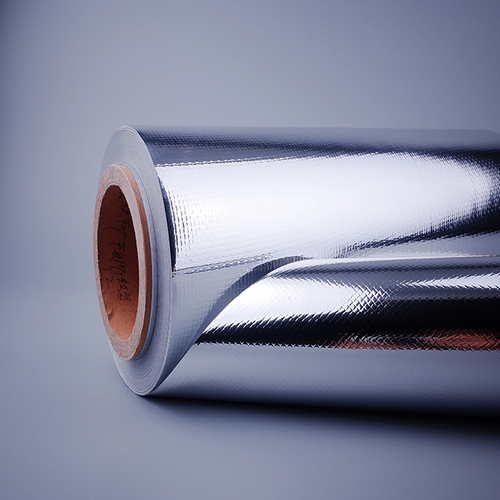

Aluminum Foil Coated Fabric is a special fabric treated with aluminum foil coating. It has excellent properties such as high temperature resistance, heat reflection, waterproof and windproof, and is widely used in many industries. This kind of fabric adds aluminum foil coating to many traditional fabrics, thereby greatly improving its functionality and is especially suitable for occasions that require specific performance.

The most notable feature of foil-coated fabrics is their excellent heat reflectivity. Aluminum foil can effectively reflect heat and block heat transfer, which makes its application in high temperature environments particularly important. Especially in high-temperature operations in summer or industrial high-temperature operations, aluminum foil-coated fabrics can effectively keep indoors cool or protect workers from high-temperature hazards.

Since aluminum foil itself has strong water tightness and wind resistance, the coated fabric also has excellent waterproof and windproof properties. This makes aluminum foil-coated fabrics very suitable for use in outdoor environments, such as tents, raincoats, outdoor equipment protection, etc., and can effectively resist harsh weather conditions.

Aluminum foil coated fabric has good high temperature resistance and can withstand higher temperatures. It can usually be used in environments between 200℃ and 300℃, which makes it widely used in the industrial field, especially in the protection and protection of high-temperature equipment. in thermal insulation material.

Aluminum foil-coated fabrics can also effectively block ultraviolet rays and prevent ultraviolet rays from damaging the human body and objects. UV radiation has a significant impact on the lifespan of many materials and products, and foil-coated fabrics can greatly extend the life of items.

Although foil-coated fabrics are versatile, they are lightweight and easy to transport and use. Compared with traditional protective materials, this fabric not only has high strength and wear resistance, but is also easier to handle and process.

The production of aluminum foil coated fabrics first requires the selection of a suitable base fabric material. Common base fabrics include polyester fiber (PET), nylon, cotton, etc. The choice of these base fabrics directly affects the durability, softness and comfort of the fabric.

After the base fabric is ready, the next step is to coat the aluminum foil onto the surface of the base fabric. Typically, aluminum foil is applied to the fabric surface through techniques such as hot pressing, coating, or evaporative deposition. In this way, the aluminum foil adheres evenly to the surface of the base fabric, giving it unique reflective and thermal insulation properties.

In order to improve the durability and performance of aluminum foil-coated fabrics, the surface of the fabric often requires further treatment, such as waterproof coating, anti-UV coating, etc. These post-processing processes can improve the functionality of the fabric and make it more durable in different environments.

After production is completed, the aluminum foil-coated fabric also needs to undergo strict inspection to ensure that its reflectivity, waterproofness, high temperature resistance and other properties meet the standards. The quality control process is key to ensuring that fabrics perform as expected in practical applications.

Aluminum foil-coated fabrics are commonly used in the manufacture of outdoor tents, raincoats, backpacks, etc. Its waterproof, windproof, high temperature resistance and other properties make it an indispensable equipment material for outdoor sports and camping.

In industrial environments, aluminum foil-coated fabrics are widely used to make insulation clothing, protective clothing, work clothes, etc., especially in high-temperature environments, which can effectively protect workers from thermal radiation and high temperature injuries.

Aluminum foil-coated fabrics also play an important role in the construction industry, particularly in building facades, roofs and insulation applications. The heat-reflective properties of aluminum foil help buildings maintain a stable temperature and reduce energy consumption.