Candy Twist Film

Material:Plastic Film

In an era where energy efficiency and environmental sustainability are at the forefront of technological innovation, heat insulation materials have become indispensable. Whether in residential homes, commercial buildings, or industrial applications, the ability to regulate temperature effectively can significantly impact energy consumption, comfort, and overall costs.

Heat insulation materials are made from various substances, each designed to meet specific needs based on factors like thermal resistance, durability, and ease of installation. Common types include fiberglass, foam, mineral wool, and reflective insulation.

Types of Heat Insulation Materials

There are various types of heat insulation materials, each suited for different applications. Some of the most common types include:

Fiberglass Insulation: One of the most widely used heat insulation materials, fiberglass insulation is made from fine strands of glass. It is highly effective at preventing heat transfer and is often used in walls, attics, and ducts. Fiberglass insulation is available in batts, rolls, or loose-fill forms and is known for its durability and fire resistance.

Foam Insulation: Foam insulation comes in several forms, including spray foam, rigid foam boards, and foam-in-place systems. It provides superior thermal performance and is often used in applications that require an airtight seal, such as sealing gaps around windows and doors or insulating walls and ceilings. Foam insulation is lightweight, cost-effective, and offers excellent moisture resistance.

Mineral Wool (Rock or Slag Wool): Mineral wool is made from natural or synthetic minerals and is commonly used in both thermal and sound insulation. It is fire-resistant, highly durable, and provides excellent heat insulation. Mineral wool is often used in high-temperature environments, such as industrial applications and building fireproofing.

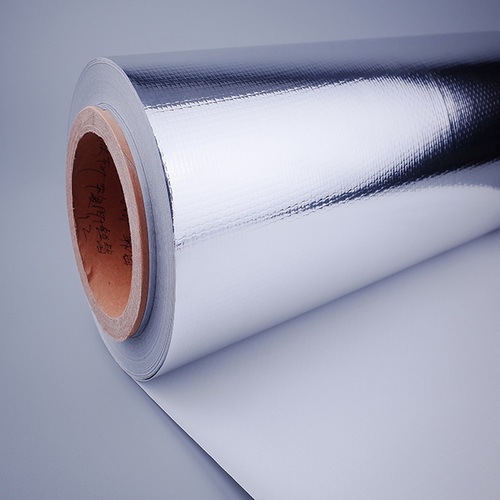

Reflective or Radiant Barrier Insulation: This type of insulation works by reflecting heat rather than absorbing it. Made of a reflective aluminum foil layer, it is particularly effective in hot climates where the primary concern is reducing the heat that enters a building. Reflective insulation is commonly used in attics or spaces exposed to high levels of radiant heat.

Cotton and Wool Insulation: For those seeking eco-friendly alternatives, cotton and wool-based insulation materials are becoming increasingly popular. These natural fibers are renewable, biodegradable, and effective at maintaining thermal comfort. Wool, for example, is particularly effective at regulating temperature and moisture, making it an ideal choice for homes in varying climates.

Cellulose Insulation: Made from recycled paper products, cellulose insulation is an environmentally friendly option that provides excellent thermal resistance. It is often used in attic and wall insulation and is treated with fire retardants to ensure safety.

Applications of Heat Insulation Materials

Heat insulation materials are used in a wide range of applications, both in residential and commercial settings. Some of the key areas include:

Residential Buildings: Insulating homes is essential for maintaining a comfortable indoor temperature throughout the year. Heat insulation materials are commonly used in attics, walls, floors, windows, and doors to reduce heat loss in the winter and minimize heat gain in the summer. Proper insulation can reduce the need for heating and cooling systems, leading to significant energy savings.

Commercial Buildings: Businesses and office buildings also benefit from heat insulation. In addition to providing thermal comfort, well-insulated buildings reduce heating and cooling costs, contributing to lower operational expenses. Heat insulation in commercial settings is also crucial for maintaining consistent indoor temperatures in environments like restaurants, data centers, and warehouses.

Industrial Applications: Heat insulation materials are essential in industries where temperature control is critical, such as in manufacturing, chemical processing, and energy production. Insulation is used to cover pipes, tanks, and boilers to prevent heat loss, improve energy efficiency, and ensure safety.

Automotive Industry: Heat insulation is also used in vehicles, particularly in engine compartments and exhaust systems, to control temperature fluctuations. Insulation in cars, trucks, and other vehicles helps maintain cabin comfort, reduce noise, and improve fuel efficiency.

Packaging and Transportation: Insulation materials are used in packaging to protect temperature-sensitive goods, such as food, pharmaceuticals, and electronics, during transportation. Insulated packaging helps maintain the desired temperature, ensuring product integrity and reducing the risk of spoilage or damage.

Benefits of Heat Insulation Materials

The benefits of using heat insulation materials go beyond just reducing energy consumption. Some of the primary advantages include:

Energy Efficiency: One of the most significant benefits of heat insulation is its ability to reduce energy consumption. By preventing heat from escaping or entering a building, insulation reduces the need for heating and cooling systems to work overtime, which leads to lower energy bills.

Comfort: Proper insulation helps maintain a consistent indoor temperature, enhancing overall comfort. During winter, insulation keeps heat inside the building, while in summer, it prevents excessive heat from entering. This makes living and working spaces more pleasant throughout the year.

Environmental Impact: By reducing energy consumption, heat insulation helps lower the carbon footprint of buildings and homes. Less energy use means fewer greenhouse gas emissions, contributing to a more sustainable environment.

Noise Reduction: Many heat insulation materials also provide soundproofing benefits, making them effective for reducing noise pollution. This is particularly useful in urban areas or commercial spaces where noise levels may be high.

Safety: Certain heat insulation materials, like mineral wool, are fire-resistant and can help prevent the spread of flames in the event of a fire. This added safety feature is crucial in both residential and industrial applications.

Cost Savings: While there is an initial cost to installing heat insulation, the long-term savings in energy bills often outweigh this expense. Over time, properly insulated buildings pay for themselves through reduced heating and cooling costs.