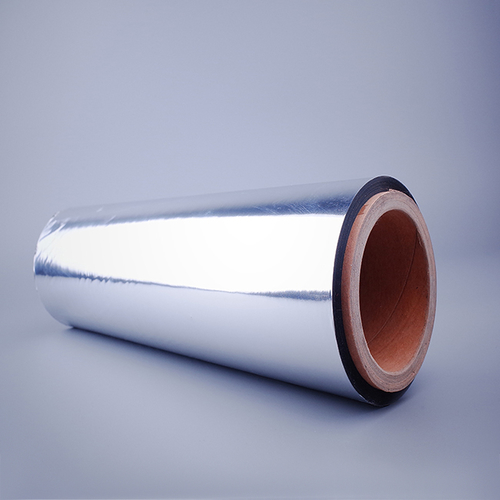

Candy Twist Film

Material:Plastic Film

Laminating Film plays a vital role in the modern packaging industry and the protection of printed products. This thin and tough plastic film is closely combined with the surface of materials such as paper, cards, and photos by hot pressing or cold pressing, which not only greatly improves the appearance texture of the product, but also gives it good waterproof, anti-fouling, scratch-resistant and tear-resistant capabilities. With the continuous increase in demand for consumer product packaging, advertising printing and graphic protection, the market application of Laminating Film is showing a diversified and high-performance development trend.

Laminating Film is usually made of plastic materials such as polyester (PET), polypropylene (BOPP) or nylon, with a layer of hot melt adhesive or pressure-sensitive adhesive on the back, which is bonded to the printed material by a laminating machine. According to different processing methods, lamination is divided into two types: thermal lamination and cold lamination:

Hot lamination: Use high temperature to melt the hot melt adhesive to achieve the bonding of the film and the printed product;

Cold lamination: No heating is required, suitable for heat-sensitive materials or low-temperature scenarios.

Common Laminating Film products include glossy film, matte film, silk film, touch film, anti-scratch film, etc., to meet different visual and functional needs.

Enhance visual effects

Glossy film presents high gloss, and the image color is more vivid and three-dimensional; matte film gives a high-end soft texture and effectively reduces reflection.

Protect printed products

The laminated material has stronger moisture-proof, oil-proof, anti-fouling and wear-resistant properties, effectively extending the product life.

Improve structural strength

Laminating Film enhances the toughness and stiffness of paper or card, avoids folding or tearing, and is suitable for commercial scenes with frequent contact.

High safety and environmental protection

Modern laminating materials mostly use non-toxic environmentally friendly glue and degradable film materials, which are in line with the development trend of green packaging.

Enhance brand image

Customized film surfaces (such as frosted film, metal film, touch film) can enhance the uniqueness and recognition of product packaging and help enhance brand value.

Commercial packaging

For example, the outer packaging boxes of food, cosmetics, electronic products, etc., can be laminated to improve the texture, anti-fouling and anti-scratch properties, ensuring the integrity of the product during transportation and display.

Graphic output and advertising display

Posters, banners, menus, business cards, covers, etc. are more attractive after lamination to prevent fading and damage.

Education and office supplies

Certificates, ID cards, teaching wall charts, work cards, etc. are more durable, waterproof, and easy to store for a long time after lamination.

Photography and art protection

Photos and paintings are treated with cold lamination, which does not affect the texture of the original work, and can also provide good protection to prevent ultraviolet erosion.

With the promotion of green environmental protection concepts and the increasing demand of consumers for high-quality packaging, Laminating Film is upgrading in the following directions:

Degradable and environmentally friendly materials: such as PLA film and recyclable PET film are replacing traditional plastics to reduce environmental burden;

Intelligent functional film: multi-layer composite films with anti-counterfeiting, antibacterial, anti-blue light and other functions will become the focus of future development;

Tactile innovation: new laminating materials such as rubber film and sand film can create a more unique tactile experience and enhance brand differentiation.

Laminating Film is not just a "protective shell" for packaging, but also an "invisible force" to beautify, strengthen and enhance product value. It combines functionality and visuality, and is a key step for printed products to move towards high-end, exquisite and durable. In the future, with the superposition of technological innovation and environmental protection demands, Laminating Film will continue to expand its application boundaries and help various industries achieve more efficient, greener and more beautiful packaging and display goals.