You may have seen it in shiny helium filled balloons, emergency space blankets, or protective plastic coatings for furniture. It is a clear, thin, reflective film with an aluminum layer deposited on both sides. It is a double aluminized polyester film and has a long and proven spaceflight heritage.

Mylar, also known as BoPET (biaxially-oriented polyethylene terephthalate), is a stretched polyester film with high transparency, reflectivity, gas and aroma barrier properties and electrical insulation. It was developed in the mid-1950s by DuPont, Imperial Chemical Industries (ICI) and Hoechst. It is less permeable to gases than aluminum foil, so it is often used as an alternative in food packaging.

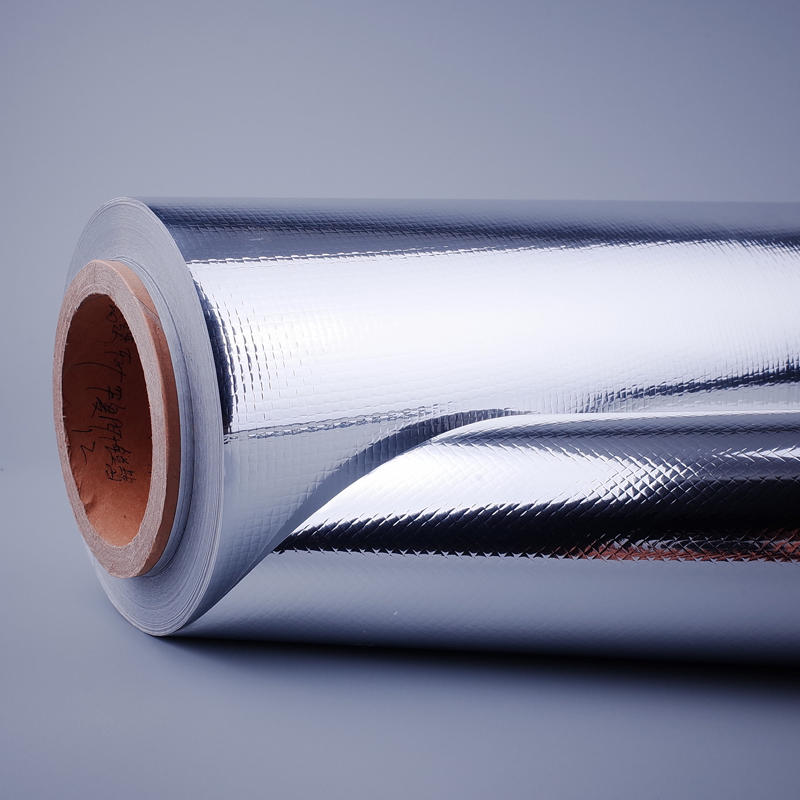

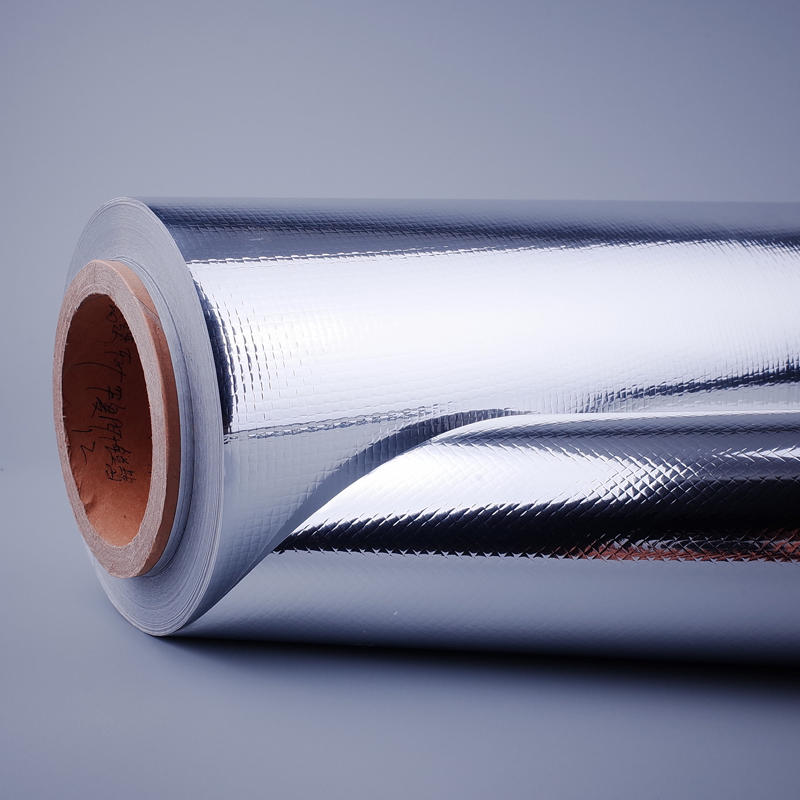

Metallized PET films are not as gas-tight as aluminium foil but they do offer a number of benefits. They are lighter, more flexible and more tear resistant than foil, less sensitive to corrosion, and not as winkle-prone. In addition, they can be printed on with solvent-based inks which are able to bond to the film surface.

Mylar is available in varying thicknesses from 1mm up to 2mm. It is not as durable as foylon but it still resists tearing, doesn’t fade and can be washed clean. It is also 90% infrared proof, so it will keep the heat within your grow room and prevent heat loss to the outside world.