Candy Twist Film

Material:Plastic Film

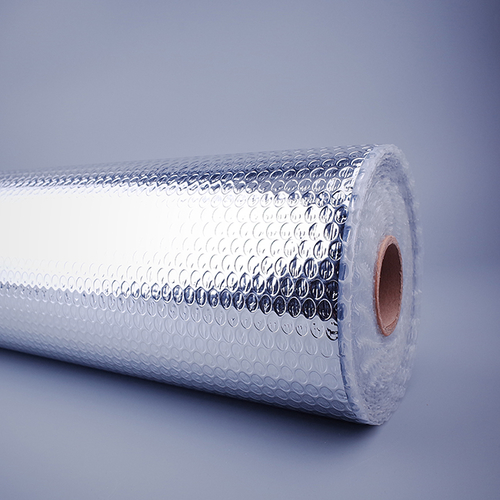

Aluminum Foil Coated Fabric is a composite material formed by coating aluminum foil material onto the surface of fabric. It combines the softness of fabric with the excellent performance of aluminum foil and is widely used in many fields, especially in occasions that require thermal isolation, radiation protection and waterproofing.

Aluminum Foil Coated Fabric, as a composite material, combines the excellent properties of aluminum foil with the flexibility of fabric. Here are some of its significant features:

Aluminum foil has good heat reflection properties and can effectively block the transfer of heat. Aluminum foil coated fabric can reflect most of the infrared radiation and prevent heat from penetrating, so it performs well in applications that need to prevent heat conduction. Whether it is heat insulation in high temperature environments or heat preservation in low temperature environments, aluminum foil coated fabric can provide effective protection.

Aluminum foil has good waterproof and moisture-proof properties. When it is coated on the surface of fabric, it can effectively prevent moisture penetration. This allows aluminum foil coated fabric to maintain its functionality under severe weather conditions and is suitable for outdoor equipment, tents and other places.

Aluminum foil can not only reflect thermal radiation, but also shield electromagnetic waves and other types of radiation. This makes aluminum foil coated cloth widely used in the field of electronic equipment protection and radiation protection.

Aluminum foil coated cloth maintains the softness and processability of the fabric, and at the same time, due to the presence of the coating, it is relatively light in weight. Its flexibility allows it to easily adapt to different shapes and sizes and is suitable for a variety of industrial needs.

The production process of aluminum foil coated cloth is relatively complex and mainly includes the following steps:

First, it is necessary to select a suitable fabric as the substrate, commonly used are polyester fiber, nylon and cotton cloth. These fabrics need to be cleaned and treated to ensure a smooth surface for the subsequent coating to adhere.

The aluminum foil is fixed to the surface of the fabric by hot pressing or coating technology. Usually, the aluminum foil is covered on the fabric in the form of a film, which ensures that the aluminum foil is evenly distributed and not easy to fall off.

The coated fabric needs to be heated and compacted to ensure that the aluminum foil is firmly attached to the surface of the fabric. Finally, the excess water and solvent are removed through a drying process to ensure the stability of the aluminum foil coated cloth.

In order to improve the anti-aging and durability of aluminum foil coated cloth, it is usually treated with anti-corrosion and waterproofing to enhance its service life in different environments.

Aluminum foil coated cloth has many excellent properties, which makes it widely used in many industries:

Aluminum foil coated cloth is often used for the exterior walls, roofs and insulation materials of buildings. Due to its excellent heat reflection and heat insulation properties, it can effectively reduce the energy consumption of air conditioning and heating. In addition, aluminum foil coated cloth is also widely used in the thermal insulation layer of solar collectors to improve energy utilization efficiency.

In the automotive industry, aluminum foil coated cloth is used in the thermal insulation layer, seats, window visors and other components of automobiles to reduce heat accumulation in the car and improve passenger comfort.

Aluminum foil coated cloth has radiation resistance, so it is used in electronic equipment, radiation protection clothing, military protective equipment and other fields. Especially in environments where electromagnetic radiation needs to be shielded, aluminum foil coated cloth can provide effective protection.

The waterproof, windproof and heat-insulating properties of aluminum foil coated cloth make it an ideal material for manufacturing outdoor products such as tents, camping mats, raincoats, etc. In bad weather, aluminum foil coated cloth can protect users from environmental influences.

In the aerospace and military fields, aluminum foil coated cloth is used to manufacture protective equipment and thermal insulation barriers. It can effectively shield radiation, and is lightweight and durable, meeting the needs of these industries for high-performance materials.

With the development of science and technology and changes in market demand, the application field of aluminum foil coated cloth is constantly expanding. In the future, with the improvement of environmental protection and energy-saving awareness, aluminum foil coated cloth will be more widely used in building energy conservation, green energy and other fields. At the same time, with the advancement of production technology, the performance and processing technology of aluminum foil coated cloth will continue to improve, especially in terms of anti-aging, high temperature resistance and versatility, aluminum foil coated cloth will show stronger competitiveness.

Aluminum foil coated cloth is a multifunctional innovative material. With its excellent thermal insulation, waterproof and windproof, radiation resistance and good processing performance, it plays an important role in many industries such as construction, automobiles, electronics, and outdoor products. With the development of technology and changes in market demand, the application of aluminum foil coated cloth will be further expanded and become an indispensable key material in more industries.