Candy Twist Film

Material:Plastic Film

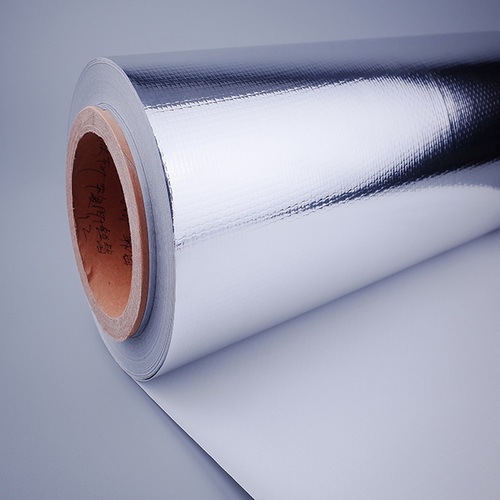

Aluminum Foil Coated Fabric is a composite material that combines aluminum foil with a textile substrate. This material has been widely used in many industries due to its unique properties, such as thermal insulation, waterproofing, corrosion resistance and electromagnetic shielding. From construction to aerospace to daily consumer products, aluminum foil coated fabrics have demonstrated their excellent versatility and adaptability.

Aluminum foil has extremely high reflectivity and can effectively reflect solar radiation and heat energy, thereby reducing heat transfer. This property makes aluminum foil coated fabric an ideal choice for thermal insulation materials, especially in high temperature environments or occasions that require energy saving.

Waterproof and moisture-proof performance

The aluminum foil layer can completely block the penetration of water and moisture, so aluminum foil coated fabrics are often used to make waterproof covers, tents and building materials. Its moisture-proof properties also make it popular in the fields of food packaging and medicine.

Electromagnetic shielding function

Aluminum foil has good conductivity and can shield electromagnetic wave interference. This makes aluminum foil coated fabrics play an important role in the protection of electronic equipment, communication facilities and military fields.

Corrosion and oxidation resistance

A dense oxide film naturally forms on the surface of aluminum foil, which prevents further corrosion and oxidation. Therefore, aluminum foil coated fabrics perform well in harsh environments, such as chemical plants or marine facilities.

Lightweight and flexible

Although aluminum foil itself is brittle, it becomes easy to bend and cut when combined with a flexible textile substrate, suitable for a variety of complex installation needs.

Manufacturing process and technological innovation

The production of aluminum foil coated fabrics mainly includes the following steps:

Substrate selection

Select a suitable textile substrate, such as polyester fiber, glass fiber or aramid fiber, according to the application. Different substrates determine the strength, heat resistance and flexibility of the final product.

Aluminum foil processing

Aluminum foil is rolled and polished to ensure that its surface is smooth and the thickness is uniform. Usually, the thickness of aluminum foil ranges from a few microns to tens of microns.

Composite process

Aluminum foil and textile substrate are combined by adhesive or hot pressing technology. In recent years, environmentally friendly adhesives and solvent-free composite technology have gradually become an industry trend to reduce the impact on the environment.

Finishing

In order to enhance specific properties, foil-coated fabrics may require additional treatments, such as coating with a protective layer, increasing fire resistance or improving tear resistance.

With the advancement of technology, the production process of foil-coated fabrics is also constantly innovating. For example, the application of nanotechnology makes the material thinner and lighter but still tough; smart sensing technology allows fabrics to have functions such as temperature regulation or humidity sensing.

Application areas

Foil-coated fabrics are widely used in many industries due to their diverse properties:

Construction and decoration

In the construction field, foil-coated fabrics are used for roof insulation, wall insulation and floor sound insulation. Its excellent thermal insulation performance helps to reduce air conditioning energy consumption and achieve energy conservation and emission reduction.

Aerospace

The aerospace industry has extremely demanding requirements for materials, and foil-coated fabrics have become an ideal choice for manufacturing aircraft insulation layers and satellite protective covers due to their lightweight and high strength characteristics.

Electronic products

The electromagnetic shielding function of foil-coated fabrics makes it widely used in electronic equipment protection, data center construction and communication base stations.

Outdoor products

In outdoor sports and emergency rescue, foil-coated fabrics are used to make tents, sleeping bags and emergency blankets. Its heat-insulating, waterproof and lightweight properties provide users with an excellent use experience.

Food and pharmaceutical packaging

Aluminum foil coated fabrics can effectively block light, oxygen and moisture, so they are widely used in food preservation, pharmaceutical packaging and cold chain logistics.

Future development trends

With the growing global demand for environmentally friendly and functional materials, the research and development direction of aluminum foil coated fabrics is moving towards greening and intelligence:

Recyclable and sustainable

Researchers are developing degradable or recyclable aluminum foil coated fabrics to reduce resource waste and environmental pollution.

Multifunctional integration

Future aluminum foil coated fabrics may integrate more functions, such as self-cleaning, antibacterial or energy harvesting capabilities, to meet diverse needs.

High-end customization

With the development of intelligent manufacturing technology, the production of aluminum foil coated fabrics will be more flexible and able to quickly customize products according to customer needs.

Aluminum foil coated fabrics have become an indispensable part of modern industry and life with their excellent performance and wide application prospects. In the future, with the continuous breakthrough of technology, this multifunctional material will surely show its value in more fields.